Know-how

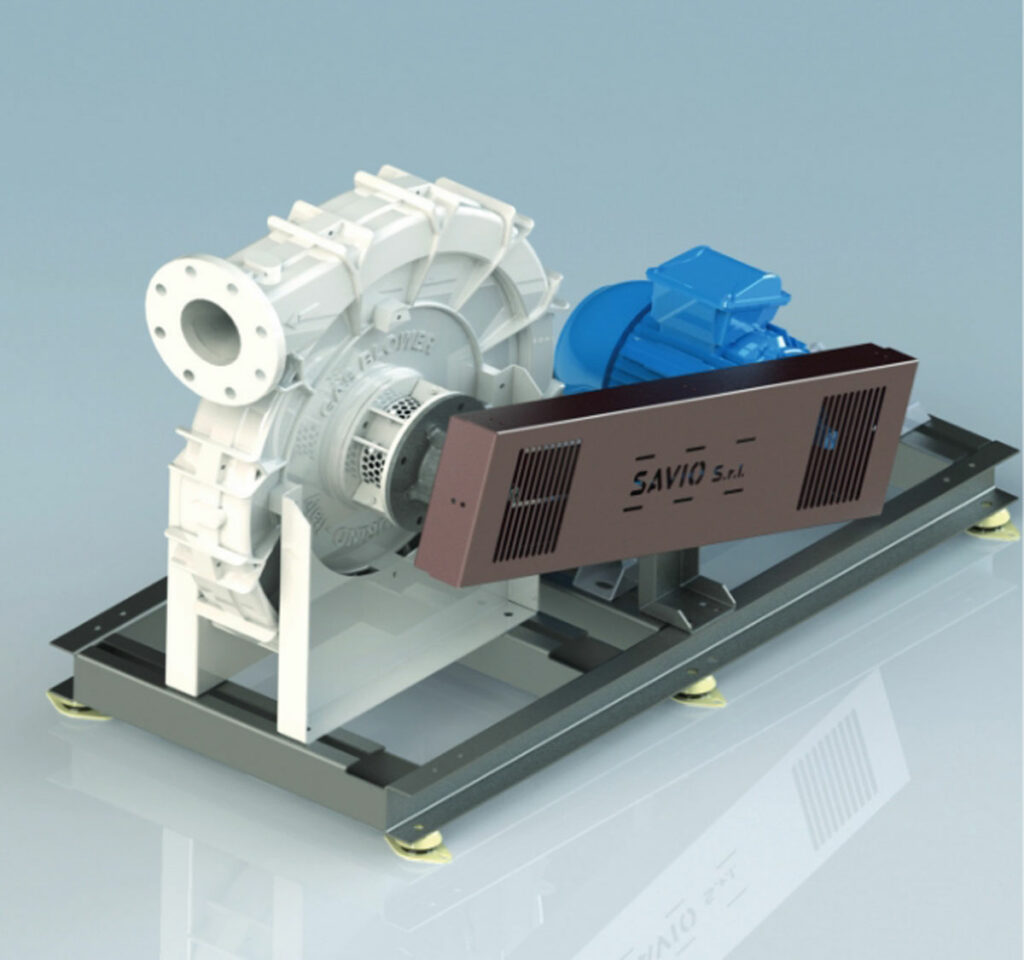

The company’s manufacturing and design capabilities are based on more than 80 years of commitment and experience in the industrial ventilation sector.

The manufacturing of air handling and air conditioning machines, of air conveying systems when polluting substances are present, with different air and gas temperatures and therefore with different conditions and specific weights, make the field of air handling extremely complex.

Savio makes its know-how available to innovate and implement its products, also through consolidated partnerships with prestigious centres such as Politecnico di Torino, Politecnico di Milano (Department of Energy and Fluid Dynamics), University College of London and engineering companies dedicated to fluid dynamics research. The combination of experience, research and innovation allowed the company to design and manufacture products, such as climatic wind tunnels, achieving excellent performance, energy saving and mechanised ventilations for coil coater rooms.

Moreover, Savio operates in high quality sectors, providing air conditioning systems for luxury yachts in shipbuilding and systems for operating rooms in hospital facilities; Savio also designs and manufactures salami storage systems for food industries and damping systems for pollution produced by pigsties.

Thanks to the excellence level in the design and manufacture of air handling systems, Savio represents a reliable point of reference for its customers and is committed to ensure continual improvement with “zero defect” production target, based on the “lean manufacturing” principle, in full compliance with the customer timing. The results of these efforts and the strength of our experience allowed the company to consolidate its offer on the Italian market and extend its production horizons, entering international markets.

Certificates

From the 1990s to the present day, Savio has become a reliable point of reference for European biogas system manufacturers thanks to the new production line of MICRO series multistage blowers suitable for conveying biogas and provided with ATEX certification.

With the aim of supplying products with quality certification and thus meeting the customer requirements, Savio achieved the UNI EN ISO 9001 2015.

It sets out the criteria for a quality management system and is the only standard in the family that can be certified to (although this is not a requirement). It can be used by any organisation, large or small, regardless of its field of activity. In fact, there are over one million companies and organizations in over 170 countries certified to ISO 9001.

This standard is based on a number of quality management principles, including a strong focus on customer, the motivation and implication of top management, the process approach and continual improvement. Using ISO 9001:2015 helps ensure that customers get good quality products and services.

ISO 9001:2015

An organisation must carry out internal audits to verify how its quality management system is operating. An organisation may decide to invite an independent certification body to verify that it complies with the standard, but accreditation is not compulsory. As an alternative, the customers could be invited to audit the quality system.

DOWNLOAD THE CERTIFICATE

DOWNLOAD THE CERTIFICATE

The ATEX directive consists of two EU directives describing which equipment (2014/34/EU) and working environment (99/92/EC) are permitted in an explosive atmosphere environment.

In order to check whether a product is suitable to operate in potentially explosive atmospheres, the manufacturer must perform the so-called ATEX analysis.

He shall consider a number of possible ignition sources in the environment where his products are installed and use the devices so that they cannot become a source of ignition.